Wood can be used to construct sophisticated buildings with a high aesthetic appeal.

Wood will play a central role in the trend of the near future: biophilic construction

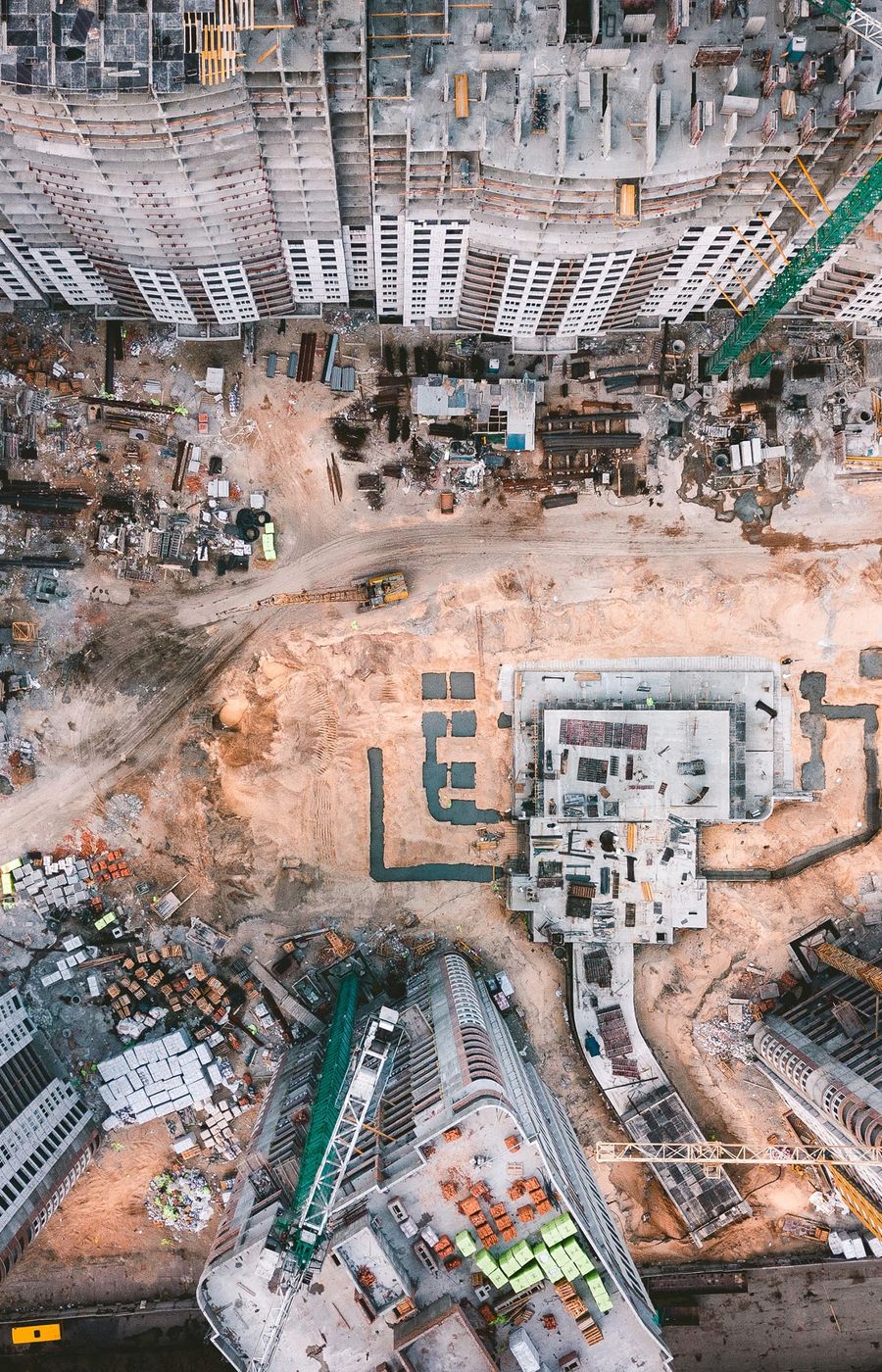

As they stand today, construction systems leave a large ecological footprint

The construction value chain accounts for at least 39% of the global CO₂ emissions

Growing environmental concerns

Using mass timber, installation costs drop about 50% while safety, resistance and durability indexes remain the same — and, in some cases, even go up.

- 01. Durable

- 02. Sustainable

- 03. Weight less

- 04. Cost Effective

The installation cost is substantially affordable, 50% cost reduction compared to the installation of other materials.

The installation cost is substantially affordable, 50% cost reduction compared to the installation of other materials.

The installation cost is substantially affordable, 50% cost reduction compared to the installation of other materials.

The installation cost is substantially affordable, 50% cost reduction compared to the installation of other materials.

Insulation and Fire Resistance

Wood is a natural insulator. So much so that is used in energy-efficient designs in some of the world’s coldest climates. It also saves a lot of space — to achieve the same degree of insulation offered by a 0.1 m thick CLT wall, you would need to build a concrete wall 1.80 m thick.

video · 02:51

Advantages of wood structures: fire resistance, low maintenance, and durability.

Fire Resistance

Wood has lower thermal conductivity than concrete, steel, and masonry. This means its fire resistance is also greater.

For instance, steel has a high thermal conductivity, affecting its resistance as temperatures increase. Actually, it is standard practice for steel to be encased in wood, to preemptively address temperature rises that would jeopardise steel’s mechanical properties. However, fire is a hazard for all buildings and construction sites — irrespective of building material.

In this scenario, another advantage of wood is that it chars on the outside while maintaining strength, slowing combustion, and allowing precious time to evacuate.

CLT Fire Resistance

Amount of time that a 10cm CLT panel wall lasted, when subjected to temperatures exceeding 980 Celsius during a fire resistance test — exceeding the 2 hours required by building codes.

Building with wood is building with nature.

Wood is an organic and natural material with a cellular structure.

The woody tissue of trees is formed by longitudinally aligned fibers, providing support to the tree and facilitating nutrient transport. Earlywood (Spring) grows rapidly, being less resistant, while latewood (Summer) grows more slowly, being darker and more durable. Density is directly linked to mechanical properties, where higher density results in greater strength and durability due to lower porosity.

Tropical woods, with more consistent year-round growth, have more homogeneous wood, making it difficult to identify growth rings. The cellular organization explains the anisotropy of wood, exhibiting distinct mechanical responses in different directions relative to the fibers.

Mechanical behavior is affected by the presence of knots, which divert fibers, reducing resistance to axial tension. Wood without knots or with smaller knots is considered of higher quality, with superior mechanical strengths. Wood is unique in allowing the prediction of its mechanical behavior through visual analysis.

Wood is only durable under certain conditions.

Erroneously, wood is often associated with low durability, but there are examples of wooden constructions that withstand for centuries. The primary agent of degradation is water, with fire being the most severe, although less frequent. The presence of water increases the moisture content in wood, creating conditions for fungi, insects, and termites. Maintaining moisture content below 20% is an effective preventive measure.

Different wood species have varied natural durabilities, and the designer should choose those most suitable for the application. If necessary, wood can be treated, but not all species are treatable in the same way. The durability of the construction depends on construction details, with emphasis on ventilation and prevention of water accumulation in contact with wood. Reducing direct contact with wood, especially in the longitudinal direction, prevents water penetration into the fibers.

Wood is easy to work with.

Wood is easy to cut and drill, which sometimes can lead to negligence or underestimation at the construction site. The perception that anyone can work with wood due to its ease often hinders wood construction. However, wood construction incorporates modern and advanced digital technologies. The emphasis on prefabrication, digitization, and Building Information Modeling (BIM) showcases the forefront of the wood industry. Wood construction is inherently prefabricated, utilizing technologies like CAD/CAM and CNC to produce elements with millimeter precision.

Wood is an anisotropic material.

Based on the analogy of wood's constitution with longitudinally oriented fibers in the trunk, it becomes simple to understand this concept. Wood exhibits different physical and mechanical performances concerning the direction of the fibers. In the direction of the fibers, the mechanical strength in tension and compression is high, but the porosity is also greater, facilitating water circulation. Meanwhile, in the perpendicular direction, the tensile strength is very low. The compression strength perpendicular is inferior to the parallel direction, but it presents a ductile behavior, skillfully exploited by carpenters in the design of connections with notches, tenons, dowels, etc.

Bonds are generally weaker than elements.

A joint represents the union of various elements, which often have different directions and inclinations. Given that wood is an anisotropic material, with properties dependent on direction, joints become the weakest elements in wood construction. These elements exhibit distinct behaviors due to different stresses in relation to the fibers.

The most common connectors in wood construction, such as screws, nails, and dowels, transmit forces mainly through shear. Although there are connectors that transfer part of the forces through axial forces, the design of joints must consider that the predominant transfer occurs through shear, with deformation of the connector and localized crushing of the wood.

What makes working with wood so special is the need to know and understand the material. For example, even with precise calculations, choosing an unsuitable wood species for the desired durability can result in a construction with a short lifespan and unsatisfactory performance. However, armed with this knowledge, building with wood becomes a fantastic experience.

The5Myths

-

“Wood burn more easily.”

“Wood burn more easily.”

If built correctly and in conformity with the construction regulations, wood has a better performance than any other system, and be constructed completely hermetically. In contrast to standard solid wood, that when exposed to high temperatures shows a large protective char layer, cross laminated timber panels, when exposed to fire, inhibit its propagation, and show a low speed or charring rate. Due to its low surface area, even without any coating, CLT panels inhibit the fire from spreading, encapsulating the flame in a restricted area and limiting its development. Another major attribute of CLT is its solid thermal mass and conductivity, meaning that, if one side of the panel is exposed to 1000 degrees Celsius, the other side will remain at ambient temperature due to its low thermal diffusivity.

01.“Wood burn more easily.”

-

“It’s necessary to bring in a specialised team to install cross laminated timber.”

“It’s necessary to bring in a specialised team to install cross laminated timber.”

The entire production process of CLT is highly industrialised, taking place in a factory, under detailed planning, where the members (panels) produced are virtually perfect, with residual error margins. The installation plan supplied by the manufacturer offers easy and fast handling, in due to the high level of prefabrication. Although they can be very large, a conventional installation team with experience in panels can easily lift, place and screw CLT panels. In fact, compared to traditional construction processes, the number of workers required to erect a CLT construction is much lower than those required to implement civil construction work with heavy construction materials, and of lower dimensions.

02.“It’s necessary to bring in a specialised team to install cross laminated timber.”

-

“Mass timber is not good for the environment, because many trees need to be felled to create the construction material.”

“Mass timber is not good for the environment, because many trees need to be felled to create the construction material.”

CLT panels are produced from wood that grows in sustainably managed forests. By enhancing the value of forestry products, we are caring for and protecting our forest. Perhaps this explains why the developed countries of Central and Northern Europe have a larger swathe of forests as a consequence of the higher value given to wood in their construction systems used in housing. Wood is the only construction material that grows naturally and is renewable. In fact, over the last 50 years, less than 2% of the inventory of standing trees in the USA has been harvested each year, while the net growth of trees has been 3%. CLT is an alternative to traditional construction, treasuring sustainable and efficient construction, able to store carbon dioxide, boosting forest renewal, which is why it is a key factor in environmental conservation.

03.“Mass timber is not good for the environment, because many trees need to be felled to create the construction material.”

-

“Wood is expensive.”

“Wood is expensive.”

If we consider the total value of a system not using CLT, it is extremely competitive in relation to the costs of other slab construction materials. But it is also necessary to consider all the added-value benefits: • The installation cost is substantially cheaper, which enables considerable savings, namely a 50% cost reduction compared to the installation of other materials. • As it is a material of low weight but high structural rigidity, wood structures, despite their large size, will weigh less than half the weight of other types of structures, leading to cost-cutting related to the foundations required to support the structures. • Safety at the workplace is drastically increased due to the CLT panels being prefabricated, and normally the only electric tools are pneumatic screwdrivers.

04.“Wood is expensive.”

-

“If there’s an earthquake, the structure will not be as resistant as other materials.”

“If there’s an earthquake, the structure will not be as resistant as other materials.”

CLT constructions give rise to a combination of resistance, ductility and low weight, comprising the ideal system to resist earthquakes. Seismic testing assure superior structural resistance and safety, especially due to its excellent mechanical properties. In Japan, a large 7-storey building was submitted to rigorous seismic tests, simulating 10 earthquakes of different intensities, having remained intact. More than replacing construction in traditional systems, or civil construction in its “modus operandi”, CLT panels seek to offer versatile and sustainable alternatives to supplement timber solutions, simultaneously offering a suitable alternative to various applications that currently use concrete and steel. This is a recent construction system with demonstrated benefits concerning thermal, acoustic, anti-fire and anti-seismic protection, proved in specific assurance and quality tests. An efficient solution, of high structural rigidity, with clear benefits to the environment.

05.“If there’s an earthquake, the structure will not be as resistant as other materials.”